Project Description

Problem:

The customer have problems onsite with their current reel setup as the hose tends to bunch up whilst travelling and making it difficult to reel out. The customer conducted some trials on a mock-up reel they made and found that a single wrap style (Mono-Spiral Wrap) reels proved to be effective to combat this. However due to the nature of the application and the size of the hoses used on these service reels, there are no current reels available in the market today that would be suited so they needed an specialist hose reel manufacturer that can offer them the right solution.

Solution:

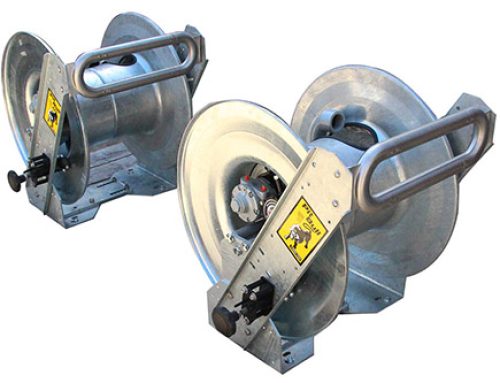

Reel Tech specialises in custom engineered reeling solutions and have the technical capabilities to provide unique solutions to many of its clients strict reeling specifications as used in heavy industries such as mining, aviation, petroleum, defence, just to name a few. After further discussion with the client on their exact requirements, Reel Tech came up with a unique reeling design, possibly a word-first, to meet their specifications which has been derived from its industry leading Pit Bull mining series reeling technology.

Hose Reels Implemented:

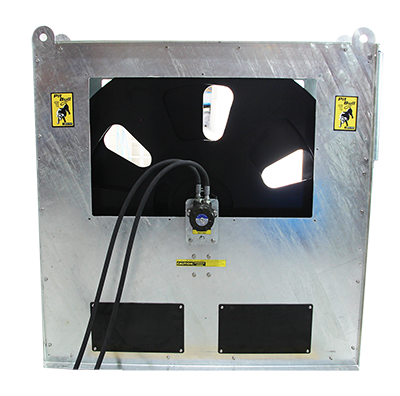

- Hose reel for diesel refuelling: With a hose capacity of 1-1/4” I.D. x 25 Metres. (HDPBMW32-76-1400STG.6K-MS) Custom PITBULL ‘mono-spiral wrap’ heavy duty reel, direct-drive hydraulic rewind, standard ‘TG’ guide arm, MS ‘quick change’ hub & riser, 600psi, 1-1/2″ NPTF In/Out, c/w 90D WHJ1590 swivel joint, galvanised frame.

- Hose reel for high pressure grease delivery: With a hose capacity of 1/2” I.D. x 25 Metres. (HDPBMW15-43-1150STG5K) Custom PITBULL ‘mono-spiral wrap’ heavy duty reel, direct-drive hydraulic rewind, standard ‘TG’ guide arm, SS ‘quick change’ hub & riser, 5000psi, 1/2″ NPTF In/Out, c/w 90D super swivel joint, galvanised frame.