Case Study

Problem: A major airline found their conventional spring retractable hose reels installed were causing damage to hose and equipment due to excessive rewind speeds and thus increasing costs to maintain and equipment replacement, not to mention possible operator injury.

Solution: The airline contacted Reel Tech whilst searching for a solution and was eager to trial Safe-R-Reel�TM to existing hose reels. After a short period of time, operators advised far safer control with rewind speeds helping guide hose onto the drum for storage and no equipment damage.

The airline has since retrofitted Safe-R-ReelTM devices to their fleet of spring rewind hose reels and standardised with Safe-R-Reel® when upgrading new hose reel equipment.

Why trust Reel Tech

For more than 25 years, Reel Tech, a proudly owned Australian company, has exclusively partnered with Hannay Reels (Made in the USA since 1933) in Australia and New Zealand.

Over this venerable time, it was clear to Reel Tech representatives that Australia’s environment and users are unique, requiring further local customisation and innovation for ‘heavy-duty equipment solutions. This led us to design solutions with patented add-ons for our hose reel range to assist operator safety.

We appreciate that we are able to assist customers locally and increase safety and efficiency simultaneously.

Contact us to learn more about how our hose reels and accessories can help your business succeed.

Ask or email our Reel Tech representative for information.

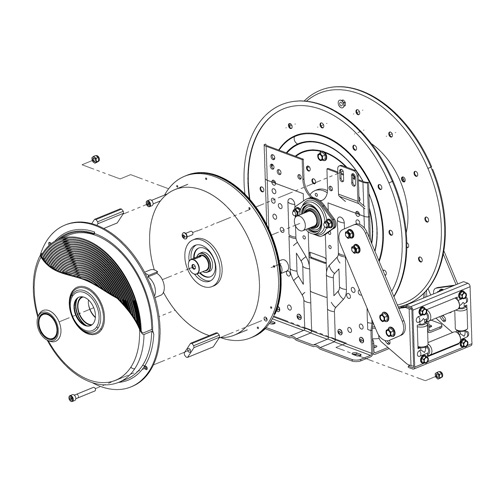

Washdown System with Rewind Control

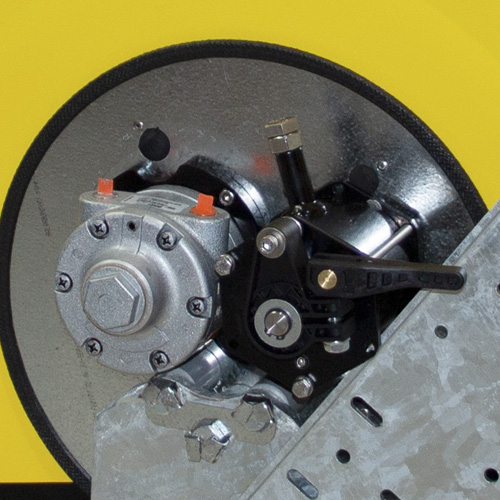

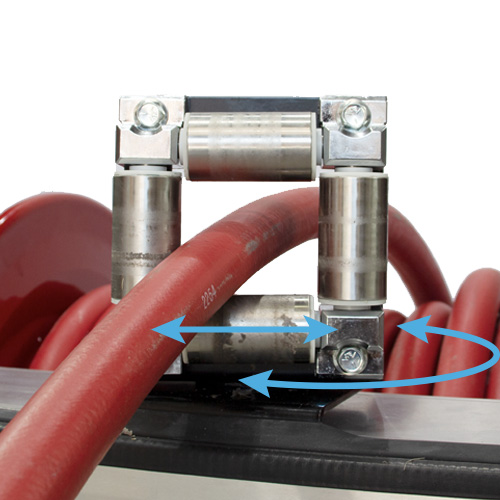

Reel Tech’s stainless steel Safe-R-ReelTM rewind speed control system reduces the chance of employee and equipment damage due to excessive hose whip during rewind, which is a common problem with spring hose reels. Another advantage of this system is that not only is it available as an option on stainless steel hose reels from Reel Tech, but it can also be fitted on existing hose reels without significant modifications. The benefit of installing Reel Tech stainless steel hose reels is that they are more robust and durable than competitor stainless steel hose reels. Installing a Safe-R-ReelTM will boost confidence in your processing reliability and safety so you can focus on other accountabilities.

Description

Spring Rewind hose reels are commonly used in various industries for hose storage, in many areas of industry including mobile equipment, plant processing, service workshops etc. A common issue many operators are confronted by is the excessive hose rewind speeds with little or no control, resulting in unnecessary injury to operators and time wasted efficiently storing hose neatly onto the hose reel.

To date, the only way to overcome dangerous hose rewind speeds was to replace the existing spring rewind hose reels with manual or powered hose reels, thus causing operators to sometimes carelessly store hose incorrectly and leave hoses laid across walkways and paths, causing tripping hazards and sometimes, even on roads where forklifts and vehicles may damage hosing and equipment. Spring rewind hose reels can be the only solution to a hazard-free and productive working environment.

Reel Tech field representatives communicated these issues to the engineering team and embarked on designing a mechanism to better control rewind speed for operators, whilst using spring rewind hose reels. The patented Safe-R-Reel™ speed control brake cassette was born, helping reduce rewind hose speeds up to 30% and above in certain circumstances, minimising the possibility of injuries whilst helping operators control the rewind of hose efficiently onto the drum of hose reels for tidy storage.

Operator Controlled rewind speeds mean:

- Reduced injury

- Reduced hose & equipment damage

- Reduced downtime