Description

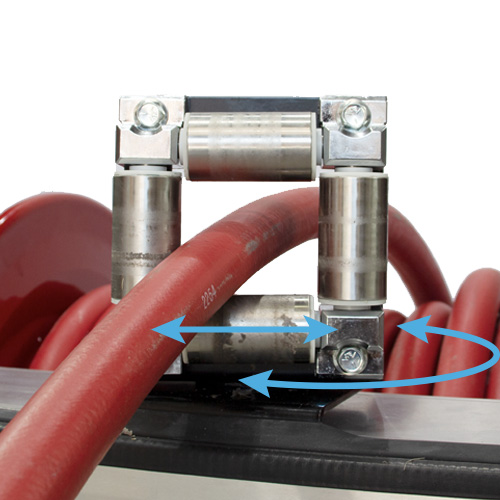

Efficient, jam-free layering of the hose during storage

Typically to rewind hose onto a hose reel, a person is required to help guide the hose back onto the reel to ensure a neat wrap is achieved. The neat wrap helps ensure that the maximum amount of hose can be stored. This means that when long lengths of hose are to be stored on the hose reel, at least two operators are required to rewind the hose back onto the hose reel. As many operations are looking at minimising personnel in the tasks, removing one of the tasks was looked at.

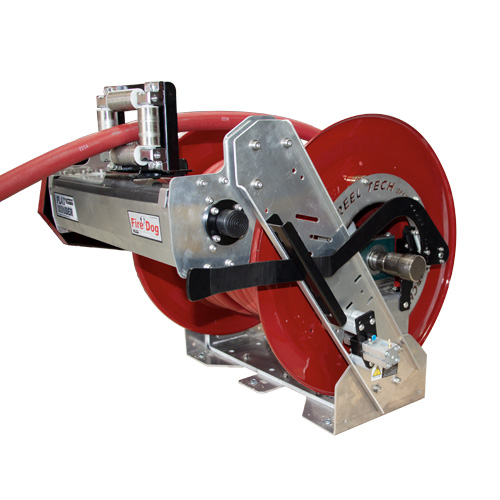

Enter, the Flat-Winder™, a device engineered to guide the hose neatly backed onto the spool of the reel; the system ensures that the maximum hose length capacity can be stored in the most space-saving fashion without any human error or intervention.

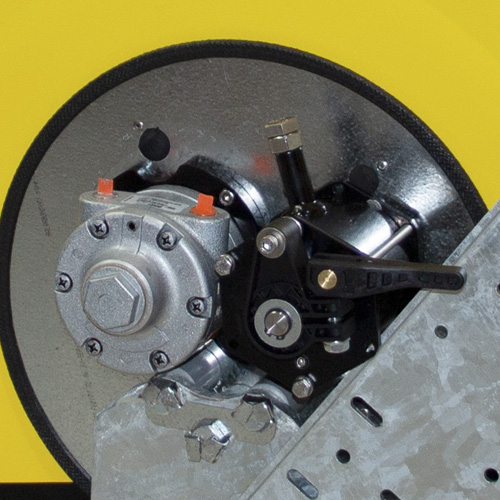

Remotely Controlled Flat-Winder™

Accommodating the increasing need to access a hose remotely, a Flat-Winder™ system capable of being controlled remotely optional progress available to make hose reel needs easier.

Corrosion Resistant Flat-Winder™

Accommodating the increasing need to use a hose reel amongst the rigours of seaside use, a fully functioning corrosion-resistant Flat-Winder™ unit has been engineered to accommodate.

Multi-Kilometre Cable Flat-Winder™

Broadening reel horizons onto unconventional areas, Reel Tech engineered a fully functioning Flat-Winder™ capable of controlling multiple kilometres of cable, whilst maintaining the maximum space-saving premise.

Heavy Duty Flat-Winder™

Venturing into the typically unforgiving environments of sewage reel applications, Reel Tech provided a custom engineered solution to strengthen to Flat-Winder™ unit to the level of robustness demanded, this fully functioning Flat-Winder™ maintained the premise of maximum space-saving.