Description

World-Patented Innovation

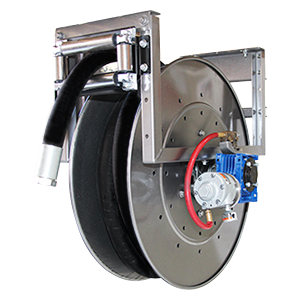

The Pit Bull hose reel is a direct drive reel system, incorporating a unique gearbox that helps provide a safe rewind speed to reduce the risk of hose whip and recoil injuries. This compact and heavy-duty design eliminates the need for an external gearbox, making it one of the safest and most reliable reels available on the market. With a focus on ergonomics, efficiency and safety, the Pit Bull was developed to serve industries where safety is essential, including:

- Mining

- Petroleum

- Defence

- Food

- Beverage

Modular, Customisable & Built to Last

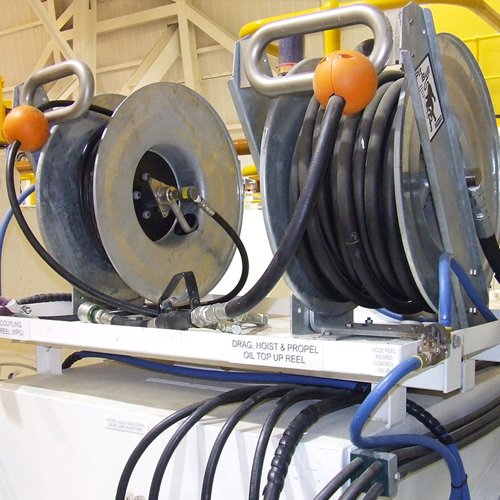

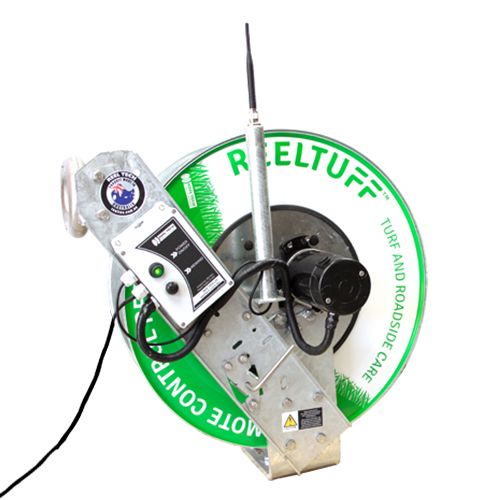

Our modular design approach means every Pit Bull hose reel can be easily adapted to suit different hose diameters, bend radii, riser configurations and more. This allows users to change components in minutes, whether they’re working with air hoses and reels or heavy duty hose reels. The modularity also simplifies retrofitting, as the reels are designed to be easily mounted to pre-existing footprints.

Available in a variety of materials, the Pit Bull comes with standard hot dip galvanising for frame and disc components, a stainless-steel hub assembly, and a hose guide for exceptional corrosion resistance. Lightweight aluminium or colour-coded steel frames are also available, giving clients flexibility depending on their specific environmental and usage conditions.

Versatile Size Options

Our expanded Pit Bull range now supports hose sizes from ½” to 2” I.D., making it a universal solution for numerous industries. Whether it’s a high pressure hose reel for industrial cleaning or a hydraulic hose reel for heavy machinery, Reel Tech can provide a solution that fits. The Pit Bull system’s compact footprint and heavy-duty build make it ideal for indoor, outdoor, mobile or underground applications. It’s no surprise the Pit Bull is fast becoming a go-to solution for business owners and engineers alike.

Backed by Expertise & Excellence

Since 1987, Reel Tech has been a trusted name across Australia and New Zealand, delivering high-quality hose reel systems backed by in-depth technical knowledge and exceptional customer service. Our team has nearly four decades of experience designing and supplying reels across industries such as steel, agriculture, mining, defence, pharmaceutical, paper manufacturing and more.

Our edge lies in our patented technologies, fast off-the-shelf availability and custom fabrication capabilities, allowing us to provide tailored hose solutions that meet precise specifications in terms of length, bend radius, weight and material.

Get in Touch Today

For businesses that prioritise safety, reliability and performance, the Pit Bull is the ultimate hose reel solution. Designed with operator wellbeing in mind and built to withstand the harshest conditions, this is a tough and dependable hose reel that truly lives up to its name. Get in touch with Reel Tech today to discover how our cutting-edge hose reel systems can transform your hose management.