Description

Optimised for Safety

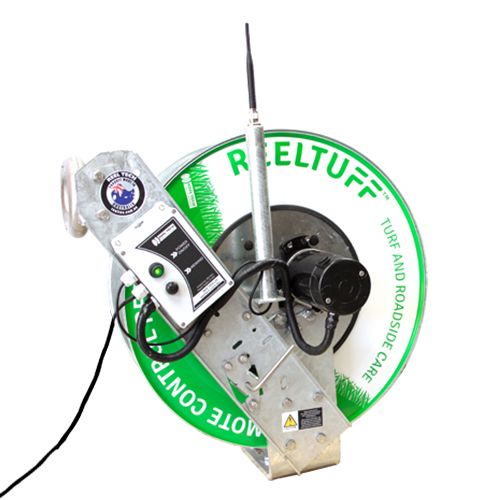

One of the standout features of our CIP hose reel options is the emphasis on safety. Traditional manual hose handling can pose a variety of risks, especially in confined or hygiene-sensitive areas. Our solution is a safer CIP hose handling system that reduces the need for operators to enter tanks or vessels during the cleaning process.

Featuring braked electric motors, these reels allow for controlled and safer rewind speeds to reduce whip hazards and strain-related injuries. Furthermore, the reels help to minimise confined space entry and lower the risk of accidents in restricted environments. These enhancements make our cleaning hose reel systems a preferred choice for facilities that prioritise safety and compliance.

Built to Dairy & Food Grade Standards

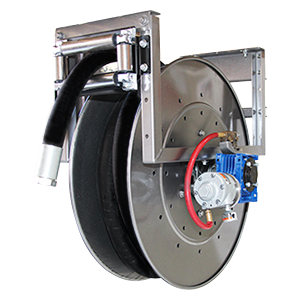

When it comes to hygiene-critical applications, Reel Tech leaves no room for compromise. Our tank cleaning hose reels are constructed with a stainless-steel hub and swivel, while the roller assemblies are made from grade 304 stainless steel. This ensures durability while maintaining the cleanliness standards required in the food and beverage sectors.

All welds are cleaned to food-grade standard, and the one-piece welded hub assembly contributes to easier cleaning and fewer bacterial harbourage points. With materials and processes aligned to dairy best practice standards, these hose reels are ideal for any CIP system where hygiene is paramount.

Smart Technology for Efficient Cleaning

Our CIP hose reel incorporates electric motors for staged cleaning, allowing for a programmed and thorough wash cycle. This innovation supports consistent and efficient cleaning, which is essential in high-throughput environments such as dairies, breweries and food processing plants. Designed to fit standard hose sizes of 2”, 2½” and 3” or customised to suit specific requirements, our reels can integrate seamlessly into existing cleaning systems. The use of current resources and technologies ensures optimal performance and compatibility with modern CIP protocols.

Tailored to Meet Industry Needs

Our cleaning-in-place (CIP) hose reel can be custom designed in a range of materials, finishes, sizes, weights and hose lengths. Optional features such as rollers and a chain guard are available upon request to further suit the operational environment and improve user safety. Whether used for a dairy plant that needs fast and effective cleaning cycles or a pharmaceutical lab that requires ultra-hygienic conditions, our CIP solutions are built to meet any challenge, with designs that emphasise ergonomics, efficiency and safety.

Backed by Decades of Expertise

With nearly 40 years of experience and a reputation built on exceptional technical advice, Reel Tech stands out as a leading manufacturer and distributor across Australia and New Zealand. Our commitment to continuous improvement, paired with in-depth product and application knowledge, positions us as a trusted partner across sectors such as mining, defence, fire services, paper, petroleum, agriculture and steel. We also have a portfolio of novel patents and proprietary systems, reflecting our innovative spirit and dedication to customer satisfaction.

Submit an Enquiry Today

Reel Tech tank cleaning hose solutions deliver unmatched performance for industries where hygiene, safety and efficiency are critical. Our CIP hose reel embodies the best of modern engineering and thoughtful design, making us the go-to choice for facilities looking to upgrade their cleaning-in-place systems. Enquire today to learn more about our state-of-the-art products.