-

CIP Tank Cleaning Hose Reel

Reel Tech is a trusted name in hose reel technology, with a premium range of CIP (Cleaning-In-Place) tank cleaning hose reels. Designed for safety, hygiene and performance, these reels reflect our commitment to delivering ergonomic and efficient solutions for a range of industries, including food and beverage, pharmaceuticals and dairy. With advanced features and robust construction, you can rest assured each cleaning hose reel meets the stringent demands of modern processing environments. -

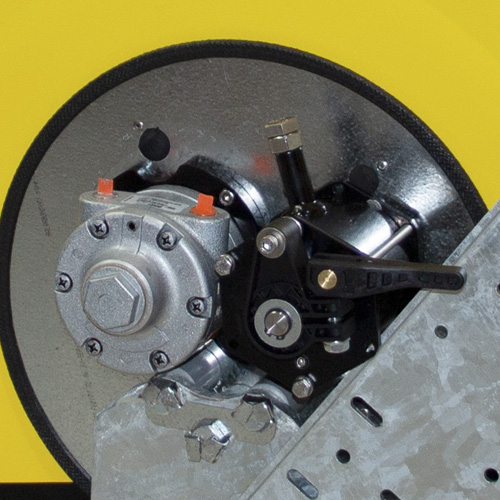

Auto declutching system

EZI-Deploy is a fully automatic hose declutching system to safely and effortlessly handle hose reels with minimal drag resistance. Reels with rewind motors are becoming more widely utilised, despite the ease of now having a motor rewind the reel for you, retrieving the hose and overcoming the added load of the motor is required great effort. Reel Tech™ has removed this problem by engineering a clutch to disengage the motor, and thus return your reel to Ezi-Deploy functionality. These clutches are capable to be remotely installed or factory fitted to help your reeling application. -

Fire Dog Hose Reels

Are you looking for reliable, safe and ergonomic hose reel systems for firefighting applications? Reel Tech’s Fire Dog hose reels lead the way in the industry. Engineered and manufactured in Australia, these fire protection hose reels are built strong and tough to handle the most demanding conditions, providing a trusted solution for emergency services and rescue operations. -

Automatic hose layering storage technology by Reel Tech

Flat-Winder™ is an automatic hose layering technology that is readily adapted to any reel for efficient easy layering of hose during storage. To minimise injuries, reduce hose damage and increase productivity.

-

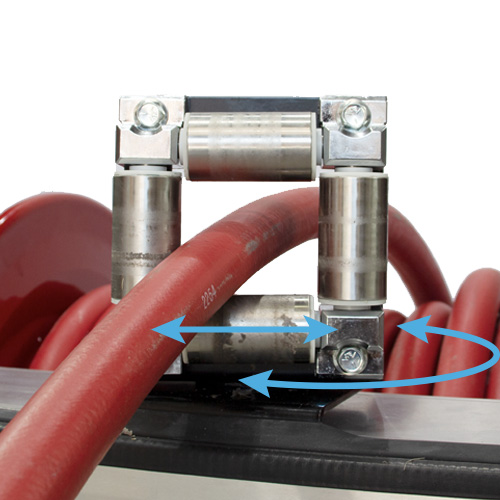

Swivelling hose guide for Flatwinder system

Market’s first multi-directional swivelling hose guide allows flexible use at any angle. A safer hose handling solution that reduces hose jam and damage.

-

Hannay Hose Reels in Australia

When it comes to efficient and high-performance hose management, Hannay hose reels stand out as the gold standard across a wide range of industries. As an authorised distributor, Reel Tech is proud to supply Hannay hose reels Australia wide that offer unmatched reliability and longevity. Built to exact specifications using only the highest quality materials, Hannay reels deliver excellent performance in the most demanding environments. Whether you’re looking for a wall mounted hose reel, a high pressure hose reel or a retract

able hose reel 30m, Reel Tech can provide what you need as one of the leading Hannay Reels distributors in the country.

-

Model AT1300

• Removable direct crank rewind reel. • Adjustable cam-lock drag brake. • 3-conductor, 45-amp collector ring is standard. • 6 foot power source lead of 10/3 cable. • 15-amp, 3-prong straight blade (optional twist lock is available). • Additional conductors available; consult factory. • Direct offset rewind crank. Aluminum Hand Truck

Model 4300-AL Part No. 9906.0795 For portability of hose and cable reels.

• Large pneumatic tires. • Reel permanently attached. • Overall dimensions will vary according to the reel model used. • Hand truck, axle, and wheels shipped separately for customer installation. Specify if reel axis is perpendicular or parallel to truck axle.

-

For stage box units.

• Rugged steel and aluminum construction. • Non-reflective black matte finish is standard. • Equipped with one durable rubber twist tie for cable ends. • Durable tray provided for storage of stage box units. • Slotted divider disc design allows connector pigtails to be safely stored alongside snake cable. • Ergonomic carrying handle. • Adjustable cam-lock drag brake.

-

-

No live connections.

Model C16-10-11

• Small, lightweight, durable. • Adjustable cam-lock drag brake. • Optional storage drum extension. • One durable rubber twist tie for cable ends. “DE” models equipped with two ties.

Model C20-14-16

• Strong, portable. • Adjustable cam-lock drag brake. • Permanent crank rewind. • Optional pin lock available. • Optional storage drum extension. • One durable rubber twist tie for cable ends. “DE” models equipped with two ties.

-

Model LC16-10-11 (Storage)

• Waterproof duplex receptacle for 3-pronged plug. • Twist lock duplex is available. • Adjustable cam-lock drag brake. • Equipped with one durable rubber twist tie for cable ends.

Series CR (Live)

• Compact, lightweight, rugged construction. • 3-conductor, 30-amp collector ring. • 6 foot power source lead with 15-amp, 3-prong straight blade plug (optional twist lock is available). • Adjustable cam-lock drag brake.

Rewind:

• Crank rewind permanent.

-

-

Pit Bull Hose Reels

When it comes it comes to performance, safety and reliability, Pit Bull hose reels from Reel Tech are second to none. Designed and manufactured entirely in Australia, the Pit Bull range is a patented heavy duty hose reel system built to meet the toughest industrial demands. From our mining hose reels Pit Bull systems to our hydraulic hose reel solutions, our commitment to ergonomic design, operator safety and technical innovation sets a new benchmark in hose management solutions. -

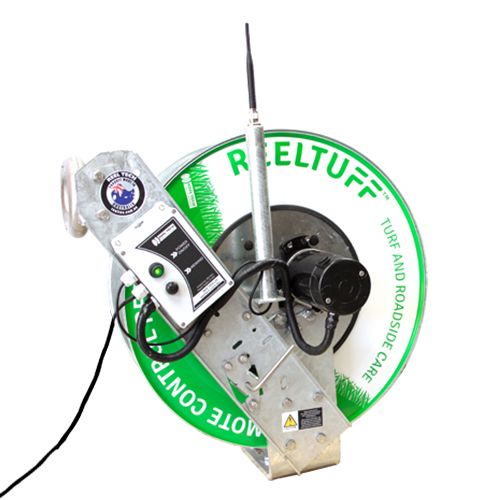

Reel Tuff Hose Reels

When it comes to managing weed spray hoses, Reel Tuff hose reels from Reel Tech are a fantastic solution. Engineered and manufactured in Australia to withstand some of the toughest environments, these high-quality reels bring durability, safety and performance to the forefront. Whether you’re maintaining golf courses, council parks, urban landscapes or roadsides, Reel Tuff hose reels are designed to enhance productivity and ease of use. -

Wireless remote control

Cut response times and increase safety with frequency hopping technology. This feature allows for safer single user operation and increased productivity. -

Rewind Speed Control System Safe-R-Reel

Reel Tech’s patented Safe-R-Reel™ easy bolt-on brake cassette ensures a controlled speed during rewind to minimise injuries and hose damage.

Stainless Steel Safe-R-Reel™, proudly Australian made and patented is carefully constructed to make winding and rewinding of the heavy-duty water hose quick and efficient. The Safe-R-Reel™ provides tidy hose storage and protection. Not to mention, excessive spring rewind speed can result from misuse causing safety issues. The impact from the rapidly moving hose can strike users, resulting in unnecessary injury. Such issues can be significantly reduced with the Safe-R-Reel™ Rewind Speed Control; it reduces the risks of injury, equipment damage, downtime and hose wear associated with excessive rewind speed. -

To handle single 1-1/4" through 1-1/2" I.D. hose.

• A strong, heavy-duty reel. • Gear-driven crank rewind or chain and sprocket drive powered by an electric, hydraulic or compressed air motor. • Optional auxiliary crank rewind for power rewind reels. • Choose EP or EPJ option. • Strap brake, standard on power rewind without auxiliary crank. • Standard inlet: 90° ball bearing swivel joint, 1-1/2" female NPT threads and 2" Victaulic® groove. • Standard outlet: flanged riser, 1-1/2" female NPT threads. • Other sizes and/or threads can be furnished and must be specified. • Standard: inlet, outlet riser, and hub assembly are steel. Options: also available in aluminum or stainless steel. • Rollers and roller mounting brackets are accessories. Specify roller position. • Chain guard is available upon request, must be specified. • Standard pressures to 600 psi (41 bar). • Temperatures from -20° F to +400° F (-29° C to +204° C). • Consult factory for other pressures and temperatures. • Reel models designed for diesel exhaust fluid (DEF) are also available

-

To handle single 1/4", 3/8" or 1/2" I.D. hose.

• Lightweight, compact with an e-coated frame. • Direct crank rewind permanently attached. • Adjustable cam-lock brake standard. • Exterior mounting holes for easier installation. • Redesigned (and field installable) pin lock. • Standard inlet: 90° ball bearing swivel joint, 1/2" female NPT threads. • Standard outlet: 3/8" female NPT threads, 1/2" available upon request. • Standard pressures to 3000 psi (207 bar), available up to 5,000 psi (345 bar) – must specify. • Temperatures from +32° F to +400° F (0° C to +204° C).

-

To handle 3/8" through 1" I.D. hose.

• Continuous flow reels with swivel joint inlet, fluid hub, outlet riser. • Direct crank rewind and cam-lock drag brake. • One-piece foot and removable steel handlebar. • GH prefix to model number (e.g., GH1100, GHAT1200) includes garden hose thread on outlet, 5' lead-in hose, hose end clips.

Model 1100 • Standard inlet: 90° ball bearing swivel joint, 1/2" female NPT threads. • Standard outlet: 1/2" female NPT threads. • Pressures to 3000 psi (207 bar). • Temperatures from +32° F to +400° F (0° C to +204° C). • Rubber tires standard.

Model AT1200 • Standard inlet: 90° balanced pressure swivel joint, 1" female NPT threads. • Standard outlet: 1" female NPT threads. • Standard pressures to 2000 psi (138 bar), available up to 4000 psi (276 bar) – must specify. • Temperatures from -65° F to +250° F (-54° C to +121° C). • Pneumatic tires standard.

-

To handle single 3/8" through 5/8" I.D. hose.

• Lightweight, compact reels designed for long lengths of hose. • Manual rewind reels include: cam-lock drag brake, spring actuated pin lock and direct crank rewind. • Power rewind reels include: chain and sprocket drive powered by electric, hydraulic or air motor. • Standard inlet: 90° ball bearing swivel joint, 1/2" female NPT threads. • Standard outlet: 1/2" female NPT threads. • Standard pressures to 3000 psi (207 bar), available up to 10,000 psi (690 bar) – must specify. • Temperatures from -40° F to +400° F (-40° C to +204° C). • Rollers and roller mounting brackets are accessory items. Specify roller position. • Optional stainless steel construction and internals – consult factory. • Optional Hose Guide Kit available (see Ordering & Accessory Guide H0415-OA, page 16). • Heavy-Duty Upgrade Options: 3/16” thick discs, 8” diameter steel 14 gage drum, and optional pressures of 5000 or 10,000 psi, must specify when ordering.

-

To handle single 5/8" or 3/4" I.D. hose.

• Lightweight, compact reels designed for long lengths of hose in manual and power rewind. • Manual rewind reels include: cam-lock drag brake, spring actuated pin lock and direct crank rewind. • Power rewind reels include: chain and sprocket drive powered by electric, hydraulic or air motor. • Standard inlet: 90° ball bearing swivel joint, 1" female NPT threads. • Standard outlet: 3/4" female NPT threads. • Standard pressures to 2000 psi (138 bar), available up to 4000 psi (276 bar) – must specify. • Temperatures from -40° F to +400° F (-40° C to +204° C). • Optional stainless steel construction and internals – consult factory. • Rollers and roller mounting brackets are accessory items. Specify roller position.

-

To handle single 1-1/2" or 2" I.D. hose.

• Gear-driven crank rewind or chain and sprocket drive powered by an electric, hydraulic or compressed air motor. • Optional auxiliary crank rewind for power rewind reels. • Strap brake on power rewind without auxiliary crank. • Standard inlet: 90° ball bearing swivel joint, 2" Victaulic® groove. • Standard outlet: flanged riser, 2" female NPT threads. • Other sizes and/or threads can be furnished and must be specified. • Standard: inlet, outlet riser, and hub assembly are steel. Options: also available in aluminum or stainless steel. • Rollers and roller mounting brackets are accessories. Specify roller position. • Standard pressures to 600 psi (41 bar). • Temperatures from -30°F to +250°F (-34°C to +121°C). • Consult factory for other pressures and temperatures.

-

To handle dual 1/4" through 1/2" I.D. hose.

• Two swivel joint inlets and two outlet risers to handle two equal lengths of hose. • Chain-driven crank rewind or chain and sprocket rewind powered by an electric or compressed air motor. • MX crank rewind reels have pinion brake as standard. • Power rewind reels are not supplied with a brake. • Standard inlets: 90° ball bearing swivel joints, 1/2" female NPT threads. • Standard outlets: 1/2" female NPT threads. • Standard pressures to 3000 psi (207 bar). • Temperatures from -40° F to +400° F (-40° C to +204° C). • Optional stainless steel construction and internals – consult factory.

-

To handle 3/4" or 1" I.D. hose.

• Economical manual rewind reels for long lengths of hose.

• Choose disc rewind or removable direct crank rewind.

• Supplied with spring actuated pin lock.

• Standard inlet: 90° ball bearing swivel joint, 1" female NPT threads.

• Standard outlet: 1" female NPT thread.

• Standard: inlet, outlet riser, and hub assembly are steel. Options: swivel joint also available in aluminum or stainless steel. Riser and hub assembly also available in stainless steel.

• Standard pressures to 2000 psi (138 bar), available up to 4000 psi (276 bar) – must specify.

• Temperatures from -40° F to +400° F (-40° C to +204° C).

• Rollers and roller mounting brackets are accessory items. Specify roller position. -

To handle 1-1/4" or 1-1/2" I.D. hose.

• Economical manual rewind reels for long lengths of hose. • Choose disc rewind or removable direct crank rewind. • Supplied with spring actuated pin lock. • Standard inlet: 90° ball bearing swivel joint, 1-1/2" female NPT threads, and 2" Victaulic® groove. • Standard outlet: flanged riser with 1-1/2" female NPT threads. • Standard: inlet, outlet riser, and hub assembly are steel. Options: also available in aluminum or stainless steel. • Standard pressures to 600 psi (41 bar), available up to 1000 psi (69 bar) – must specify. • Temperatures from -20° F to +212° F (-29° C to +100° C). • Rollers and roller mounting brackets are accessory items. Specify roller position.

-

To handle dual 1/4" through 1/2" I.D. hose.

• Two swivel joint inlets and two outlet risers to handle two equal lengths of hose. • Chain-driven crank rewind or chain and sprocket rewind powered by an electric or compressed air motor. • MX crank rewind reels have pinion brake as standard. • Power rewind reels are not supplied with a brake. • Standard inlets: 90° ball bearing swivel joints, 1/2" female NPT threads. • Standard outlets: 1/2" female NPT threads. • Standard pressures to 3000 psi (207 bar). • Temperatures from -40° F to +400° F (-40° C to +204° C). • Optional stainless steel construction and internals – consult factory.

-

To handle 3/4" or 1" I.D. hose.

• Lightweight, compact reels designed for long lengths of hose in manual and power rewind. • Manual rewind reels include: gear-driven crank rewind with removable handle and adjustable brake. • Power rewind reels include: chain and sprocket drive powered by electric, hydraulic or air motor. • Standard inlet: 90° ball bearing swivel joint, 1" female NPT threads. • Standard outlet: 1" female NPT threads. • Standard pressures to 2000 psi (138 bar), available up to 4000 psi (276 bar) – must specify. • Temperatures from -40° F to +400° F (-40° C to +204° C). • Rollers and roller mounting brackets are accessory items. Specify roller position.

-

To handle dual 1/4" through 3/4" I.D. hose.

• Rollformed channel frame for heavy-duty applications. • Non-sparking ratchet assembly. • Declutching arbor to prevent damage from reverse winding. • Standard inlets: 90° full-flow swivel joints with Viton® seals, 1/2" female NPT threads (1" inlet available). Must be specified. • Optional balanced pressure (BP) swivel joints are available upon request. Subtract 1-3/4" from “F” dimension. • Standard outlets: 1/2" female NPT threads (3/4" outlet available). Must be specified. • Standard pressures to 3000 psi (207 bar), available up to 10,000 psi (690 bar) – must specify. • Temperatures from -40° F to +400° F (-40° C to +204° C). • 4-way roller assembly. SR position is standard, other configurations available, must specify. • Constant tension is available – consult factory. • Reels for use with oxygen/acetylene. See Series N400

-

To handle single 1/2" through 1" I.D. hose.

• Heavy-duty reel for longer lengths of hose. • Choose gear-driven crank rewind or chain and sprocket drive powered by an electric, hydraulic or compressed air motor. • Crank rewind reels supplied with pinion brake; power rewind reels with a strap brake. • Standard inlet: 90° ball bearing swivel joint, 1" female NPT threads. • Standard outlet: 1" female NPT threads. • Standard: inlet, outlet riser, and hub assembly are steel. Options: swivel joint also available in aluminum or stainless steel. Riser and hub assembly also available in stainless steel. • Standard pressures to 2000 psi (138 bar), available up to 5000 psi (345 bar) – must specify. • Temperatures from -40° F to +400° F (-40° C to +204° C). • Rollers and roller mounting brackets are accessory items. Specify roller position. • Optional chain guard available upon request, must be specified. * Heavy-duty construction required for water blasting and sewer cleaning applications. Consult factory.

-

To handle single 3/8" through 1/2" I.D. hose.

• Rugged construction. • Strong spool to control hose expansion. • Standard inlet: 90° ball bearing swivel joint, 1/2" female NPT threads. • Standard outlet: 1/2" female NPT threads. • #40 chain and sprocket drive. • Hydraulic, Air and Electric motorized rewinds are available. • Steel-Hub Assembly – rated to 5000 psi (345 bar).

Options

• 10,000 psi working pressure (690 bar). • Auxiliary rewind. • Roller assemblies. • Chain guard. • Hose packages.